Equipment and installation methods

Installation equipment

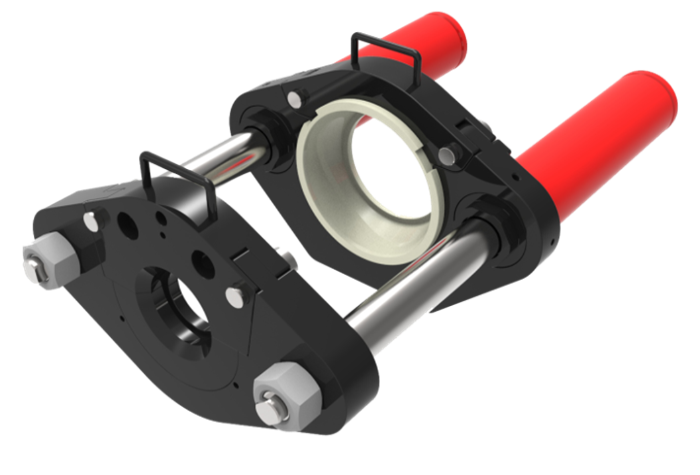

Hydraulic press (Version No. 1)

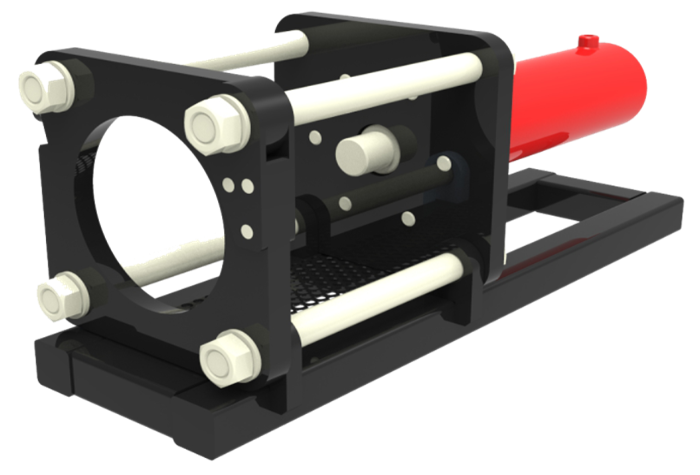

Hydraulic press (Version No. 2)

Equipment to coil / uncoil pipeline

- A-frame (OU);

- Pay of and take up equipment (POU).

Ways of STV mounting

Trench pipe-laying

In comparison with steel pipelines STV requires 20-40 % less width of a trench and decreases the installation time by several times. STV does not have any special requirements to a bed plate, however in order to prevent outer sheath damages the areas contacting the pipe should not have big, sharp stones or bulges. Passages under the road as a rule go to a manifold pipe.

Above-ground pipe-laying

Using method of direct laying it is possible to set up multiple lines in a quick and effective way. Usually during laying there is no need in any supports and ramps which are used with steel pipes. However, STV can be installed in existing pipeline routes using these constructions.

Pipeline Relining

STV can be installed instead of old pipes of bigger diameter by pulling the flexible composite pipeline through the opening the existing one. There is a successful experience of pulling one segment of the pipe with the length up to 1.2 km including several bends. The main restriction is the length of a guide pipe, which should be preliminary pulled through the pipeline to be relined.

Installation in severe climatic conditions

STV can also be installed above the ground and ideal for applications in areas with severe climatic conditions, such as Arctic regions. STV does not lose its strength characteristics at low ambient temperatures.

Underwater pipe-laying

Except for the abovementioned installation methods STV can be installed under water at depths up to 120 m. This kind of installation is applied to mount the pipeline both in fresh and sea water. Offshore pipelines are generally used for oil and gas transportation but can be used for transportation of other products, for example fresh water.